Tag: astro pi

All blog posts-

Community Story | Daniela, Thetford Library

Discover how Daniela found her passion for coding while leading a Code Club at Thetford Library

-

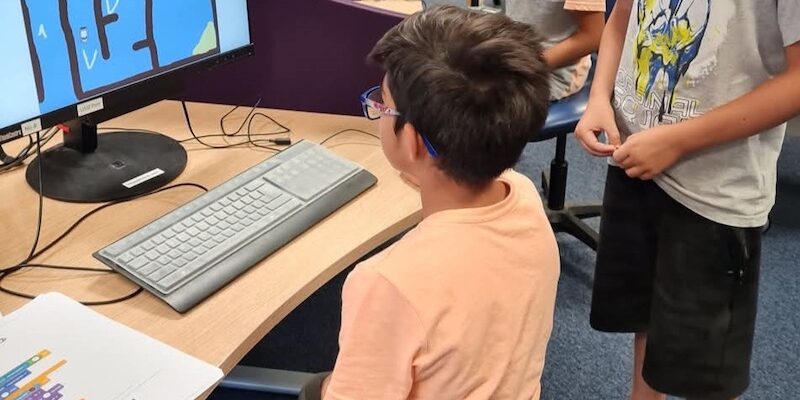

Five reasons to join the Astro Pi Challenge, backed by our impact report

Learn how the Astro Pi Challenge benefits young people and mentors, with insights from our report

-

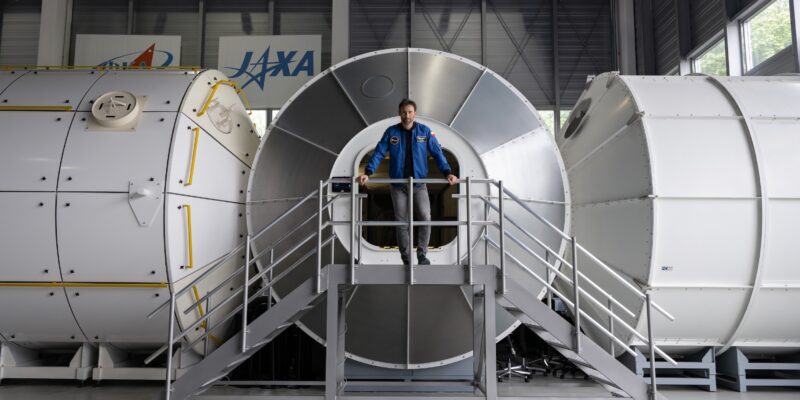

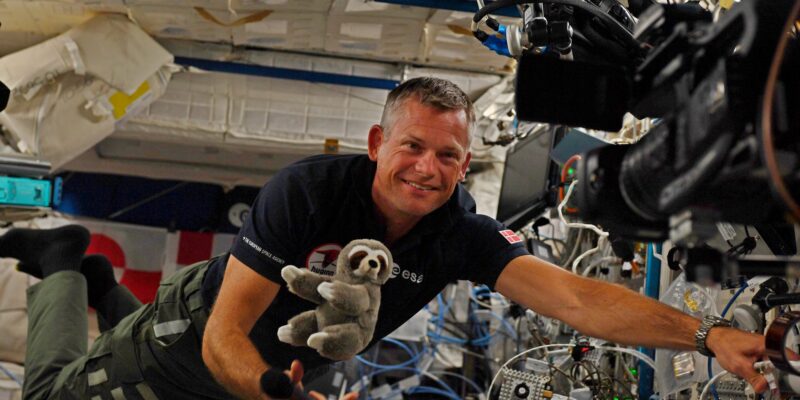

The European Astro Pi Challenge 2024/25 launches today

Sending young people's code to space, with ESA project astronaut Sławosz Uznański as ambassador

-

Celebrating Astro Pi 2024

Mission Zero and Mission Space Lab give young people the confidence to engage with technology

-

Young people receive their data from space and Astro Pi certificates

In this round of Astro Pi, over 26,400 young people took part across its two missions

-

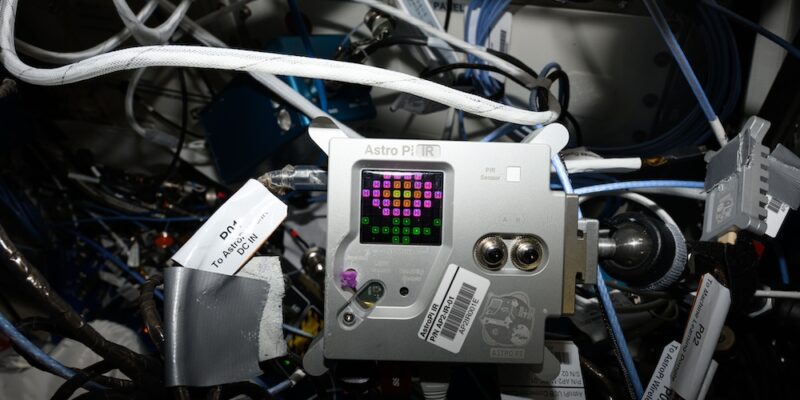

Young people’s Astro Pi code is sent to the International Space Station

Astro Pi Challenge sends thousands of programs into space this year

-

Get ready for Mission Space Lab with our new simulation tool

New resources and tools to support young people and mentors

-

Celebrating the community: St Joseph’s Secondary School

Discover the story of how one school's student community has grown strong through coding

-

Explore space science and coding with Astro Pi Mission Space Lab

We support young people and mentors to take part

-

Launch kids’ code into space with the European Astro Pi Challenge 2023/24

Astro Pi Mission Zero opens today

-

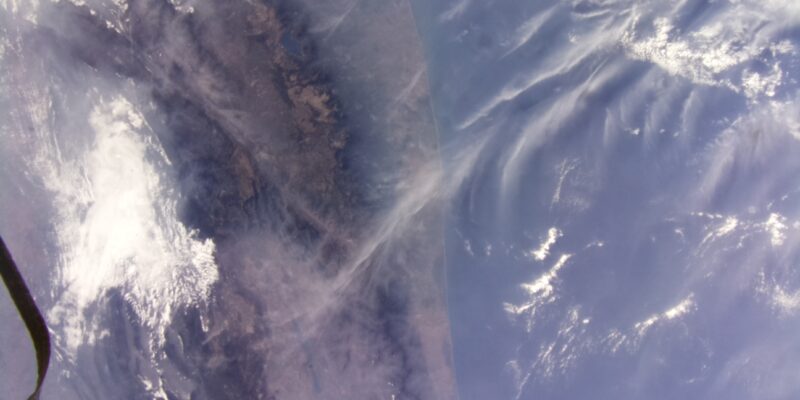

Young people’s amazing experiments in space: Astro Pi Mission Space Lab 2022/23

Celebrating another year of young people's computer programs in space

-

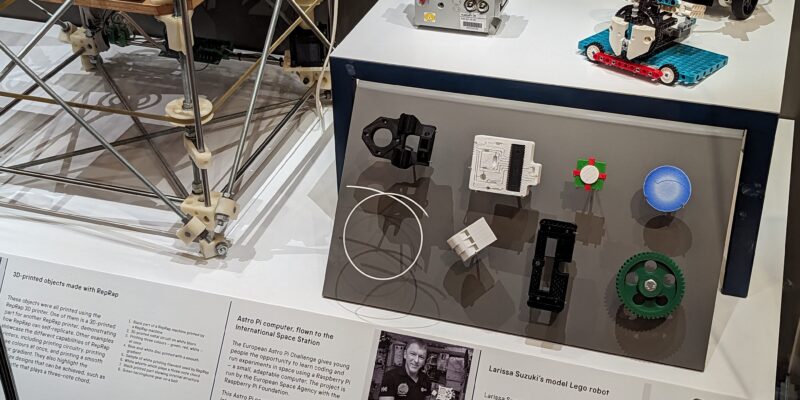

Welcome home! An original Astro Pi computer back from space is now on display at the Science Museum

The original two Astro Pi computers that we sent to the ISS have returned to earth.