Tag: Community stories

All blog posts-

Community Story | Daniela, Thetford Library

Discover how Daniela found her passion for coding while leading a Code Club at Thetford Library

-

Celebrating the community: Prabhath

Find out how Prabhath is bridging the STEM education gap in Sri Lanka

-

Celebrating the community: Isabel

Meet Isabel, a computer science teacher who empowers a new generation of diverse tech professionals

-

Celebrating the community: Yang

Meet Yang, a Manager in Technology Consulting at EY whose commitment to CoderDojo is truly inspiring

-

Celebrating the community: Arno & Timo

Timo and Arno support and inspire the next generation of coders

-

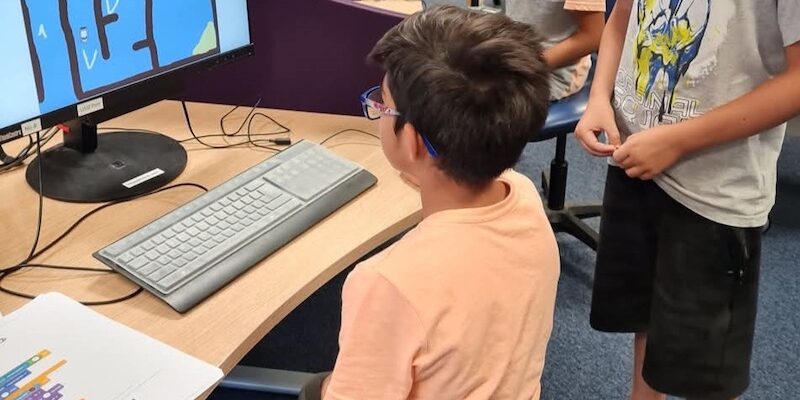

Celebrating the community: Micah

Micah is learning coding and gaining confidence at his library's Code Club in Leeds

-

Celebrating the community: Sahibjot

Discover how Sahibjot’s passion for computing has helped shape his aspirations

-

Celebrating the community: St Joseph’s Secondary School

Discover the story of how one school's student community has grown strong through coding

-

Celebrating the community: Spencer

One passionate teacher's journey from science to computer science

-

Celebrating the community: Nadia

Working towards a Code Club in every school in Iraq

-

Celebrating the community: Adarsh

Watch this young tech creator's story to see how he has learned from the community

-

Celebrating the community: Sophie

Watch the story of this inspiring teacher and her school's Code Club