Tag: computer science

All blog posts-

Ada Computer Science: What have we learnt so far

Discover how students and teachers are benefiting from our free online learning platform

-

Ada Computer Science: A year in review

A reflection on Ada Computer Science over the past twelve months.

-

Celebrating the community: Isabel

Meet Isabel, a computer science teacher who empowers a new generation of diverse tech professionals

-

How we’re creating more impact with Ada Computer Science

User feedback shows positive impact on learning and teaching

-

Launching Ada Computer Science, the new platform for learning about computer science

Free, high-quality resources for young people all over the world to learn about computer science

-

Say hello to Isaac Computer Science

A new online platform for teachers and students of A level Computer Science...

-

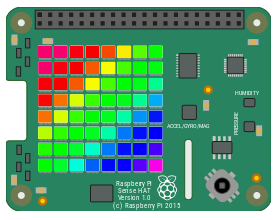

Desktop Sense HAT emulator

Play with a free Sense HAT on your Raspberry Pi desktop!

-

Astro Pi: Mission Update 9 – Science Results

A summary of the Astro Pi science results

-

University of York: Raspberry Pi Challenge 2015

Our Gordon Hollingworth judges York undergrads in the Raspberry Pi Challenge

-

Computer Science added to EBacc

If you’re at BETT this week, come over to Stand B240 to meet one of the