Experience AI expands to reach over 2 million students

Two years ago, we announced Experience AI, a collaboration between the Raspberry Pi Foundation and Google DeepMind to inspire the next generation of AI leaders.

Today I am excited to announce that we are expanding the programme with the aim of reaching more than 2 million students over the next 3 years, thanks to a generous grant of $10m from Google.org.

Why do kids need to learn about AI

AI technologies are already changing the world, and we are told that their potential impact is unprecedented in human history. But just like every other wave of technological innovation, along with all of the opportunities, the advancement of AI has the potential to leave people behind, to exacerbate divisions, and to create more problems than it solves.

Part of the answer to this challenge lies in ensuring that all young people develop a foundational understanding of AI technologies and the role that they can play in their lives.

That’s why the conversation about AI in education is so important. A lot of the focus of that conversation is on how we harness the power of AI technologies to improve teaching and learning. Enabling young people to use AI to learn is important, but it’s not enough.

We need to equip young people with the knowledge, skills, and mindsets to use AI technologies to create the world they want. And that means supporting their teachers, who once again are being asked to teach a subject that they didn’t study.

Experience AI

That’s the work that we’re doing through Experience AI, an ambitious programme to provide teachers with free classroom resources and professional development, enabling them to teach their students about AI technologies and how they are changing the world. All of our resources are grounded in research defining the concepts that make up AI literacy, they are rooted in real-world examples drawing on the work of Google DeepMind, and they involve hands-on, interactive activities.

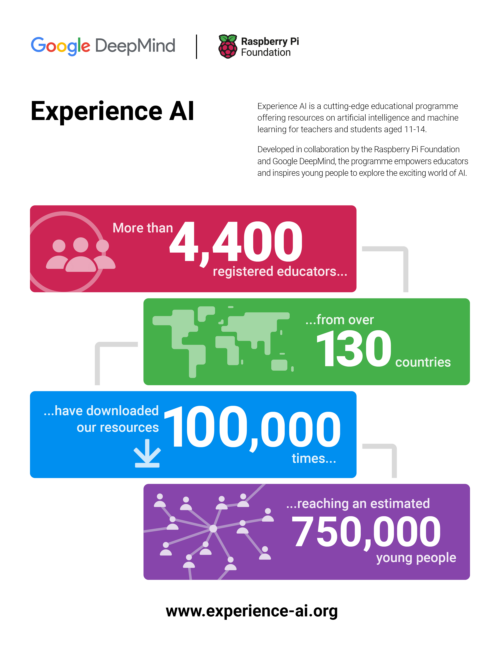

The Experience AI resources have already been downloaded 100,000 times across 130 countries, and we estimate that 750,000 young people have taken part in an Experience AI lesson so far.

In November 2023, we announced that we were building a global network of partners that we would work with to localise and translate the Experience AI resources, ensuring they are culturally relevant, and to organise locally delivered teacher professional development. We’ve made a fantastic start working with partners in Canada, India, Kenya, Malaysia, and Romania, and it’s been brilliant to see the enthusiasm and demand for AI literacy from teachers and students across the globe.

Thanks to an incredibly generous donation of $10m from Google.org — announced at Google.org’s first impact summit — we will shortly be welcoming new partners in 17 countries across Europe, the Middle East, and Africa, with the aim of reaching more than 2 million students in the next three years.

New resources on AI safety

Alongside the expansion of the global network of Experience AI partners, we are also launching three new resources that focus on critical issues of AI safety:

AI and your data: Helping young people reflect on the data they are already providing to AI applications in their lives, and on how the prevalence of AI tools might change the way they protect their data.

Media literacy in the age of AI: Highlighting to young people the ways AI tools can be used to perpetuate misinformation, and how AI applications can help combat misleading claims.

Using generative AI responsibly: Empowering young people to reflect on their responsibilities when using generative AI, and their expectations of developers who release AI tools.

Get involved

In many ways, this moment in the development of AI technologies reminds me of the internet in the 1990s (yes, I am that old). We all knew that it had potential, but no-one could really imagine the full scale of what would follow.

We failed to rise to the educational challenge of that moment and are still living with the consequences of that failure: a dire shortage of talent; a tech sector that doesn’t represent all communities and voices; and young people and communities who are still missing out on economic opportunities and unable to use technology to solve the problems that matter to them.

We have an opportunity to do a better job this time. If you’re interested in getting involved, we’d love to hear from you.

1 comment

Jump to the comment form

ally tumelo mphahlele

Good morning

Please consider us in any opportunity to lift up our youth in our community thanks